・Highly rinsable and volatile (can be washed with only one liquid. No additional cleaning required. Can be naturally dried)

・High safety (uses low-toxic main ingredients that are also used as food additives)

・High detergency (thickening resin, oil and fat can be dissolved and removed)

・Friendly to the environment and human body (not applicable to Poisonous and Deleterious Substances Control Law, Organic Law, PRTR, Water Pollution Control Law, etc.)

| Product name | TSC-100 |

| Appearance | colorless and transparent |

| Odor | Slightly peculiar ester odor |

| pH | not applicable |

| Relative density | 1.01 to 1.05 at 25 deg C |

| Viscosity | 1.0 to 3.0 (mPa/s at 25 deg C) |

| Flash point(deg C) | 59-63 |

| Fire Service Act | Dangerous Goods Class 4, Petroleum Water-Soluble Liquid, Danger Class III |

| LD-50 (mg / kg) | No data |

| Soluble | Mixable with water, ethanol, IPA acetone |

Mold flat plates under the same conditions and compare their cleanability.

Evaluation conditions: Primary cleaning → Secondary cleaning → Drying 30 minutes → UV treatment (2 times on the front and back / 2 minutes each)

TSC-100 only

TSC-100 only

Immediately after cleaning, it has a smooth cleaning property. After one day, the surface of the model becomes glossy.

Recommended cleaning agent

Recommended cleaning agent

The model loses its luster and has a clean finish.

Our primary cleaning agent + secondary cleaning agent

Our primary cleaning agent + secondary cleaning agent

A little gloss remains. Washing due to the use of 2 liquids Cleanliness is good, but it takes time.

* The photos shown are printed and may differ slightly from the actual colors.

* Please note that the specifications described are subject to change without notice..

* The specifications shown are as of August 2021.

There is a method called numerical simulation by computer analysis. Environmental information such as flow path and fluid characteristics can be input numerically, and the calculation results can be numerically and visualized for recognition.

There is a method called numerical simulation by computer analysis. Environmental information such as flow path and fluid characteristics can be input numerically, and the calculation results can be numerically and visualized for recognition.

However, You often hear that it is difficult to completely match the analysis results because there are many irregular factors that cannot be quantified and input for the actual movement of the fluid.

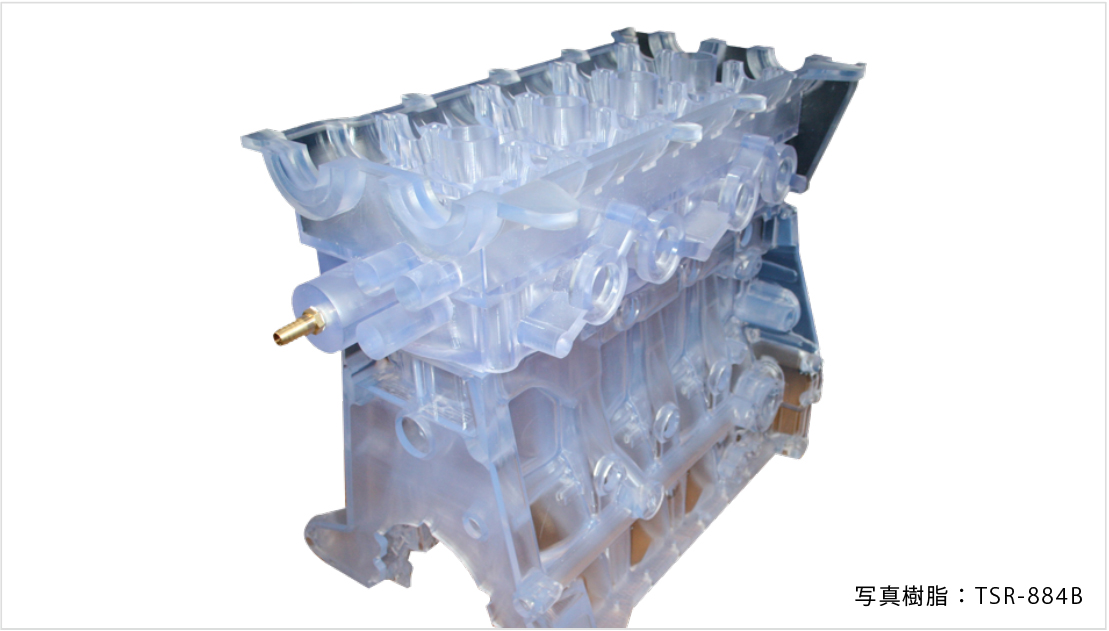

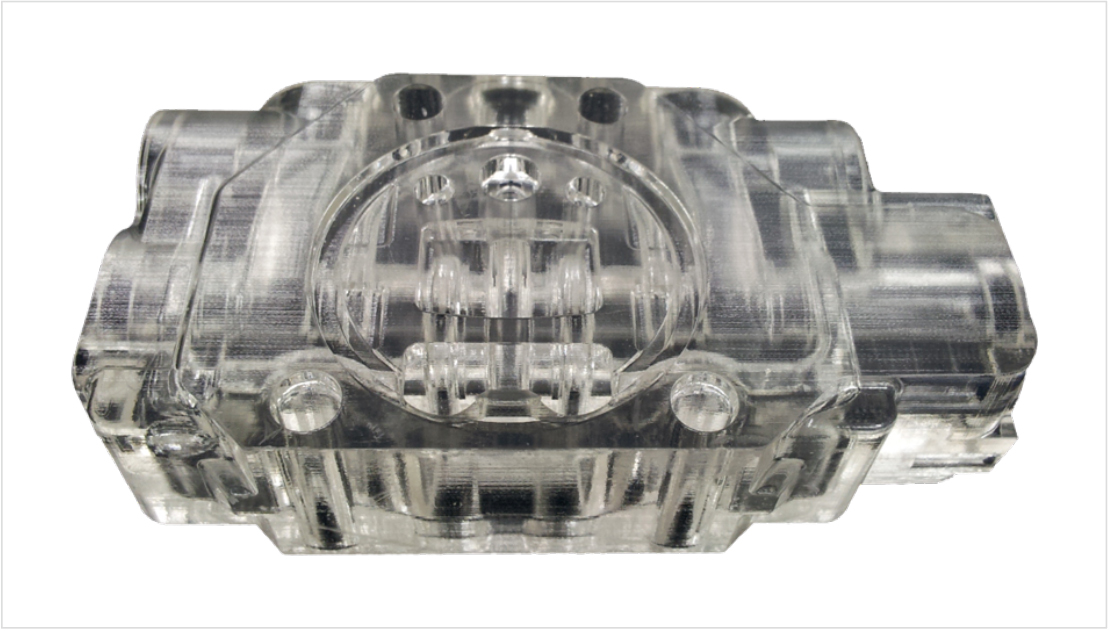

The transparent stereolithography resin modeled by CMET solves such a problem. The following example of an automobile engine is just one of them, and you can easily check the detailed results of computer simulation.

When this method is used, even an engineer who does not have detailed knowledge of simulation data can visually check it, so it will be an advantage to have a sufficient sense of conviction.

We strongly recommend this method for engineers who want to quickly and accurately grasp the movement of fluids such as gases and liquids and realize front-loading of development.

By photographing the behavior of particles with a camera etc., you can see the traces of particles flowing in chronological order. You can also observe the internal turbulence compared to the simulation.

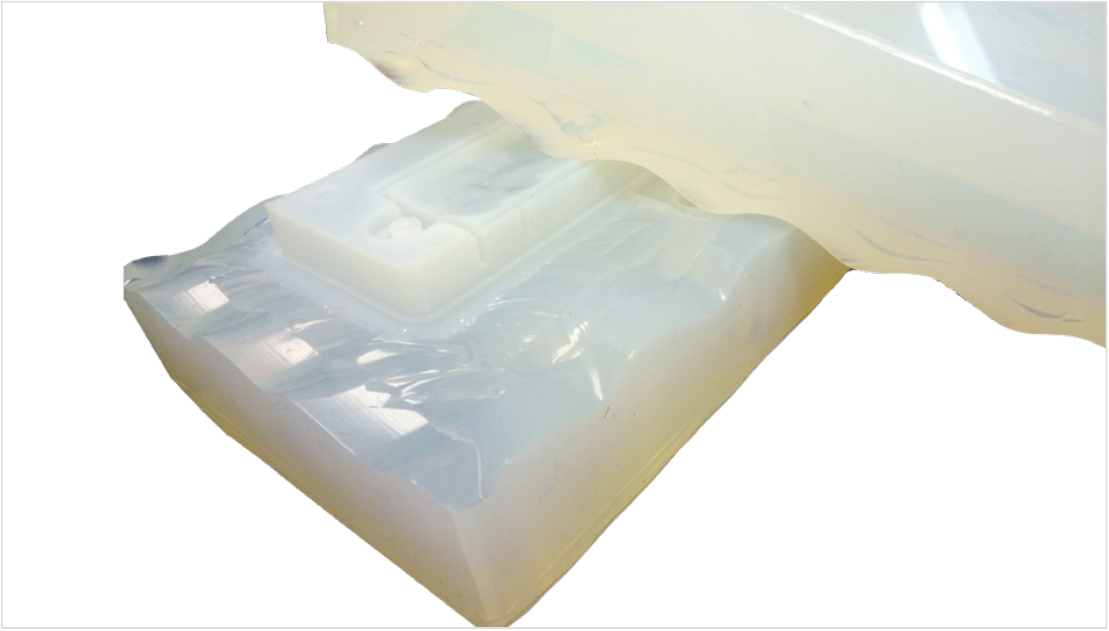

Vacuum casting may be effective when making multiple identical parts.

Vacuum casting may be effective when making multiple identical parts.

[What is vacuum casting]

It is a construction method to make a replica with hard or soft urethane using a stereolithography product or a machined product as a master model.

To utilize the stereolithography model as a master The stereolithography model is characterized by high dimensional stability, good stacking removal property on the design surface, good surfacer coating property, and good compatibility with silicon for casting.

It can be manufactured in a shorter delivery time than the conventional cutting master and is basically lower cost than the cutting master.

In addition, since the angle R is not formed by the blade, it is possible to manufacture cast products that are as faithful as possible to actual 3D.

The accuracy is slightly inferior to that of the cutting master. In addition, the master model may be damaged depending on the shape when the master is removed from the cast silicon mold.

By applying surface treatment to the master model, the cast product will have the same surface.

Regarding the design surface, it is necessary to polish and remove the contour line-like pattern (lamination step) that occurs in the lamination method.

Visualization with highly transparent and highly heat-resistant resin “TSR-884”.

Visualization with highly transparent and highly heat-resistant resin “TSR-884”.

The transparent heat-resistant resin “TSR-884” is an eco-friendly non-antimony type resin.

Heat treatment improves heat resistance up to 100 ℃ or higher.

The TSR884 is the world’s first to be assembled with a resin that has both “heat resistance” and “transparency”, and the inside can be visualized.

[What is Stereolithography Precision Casting]

[What is Stereolithography Precision Casting]

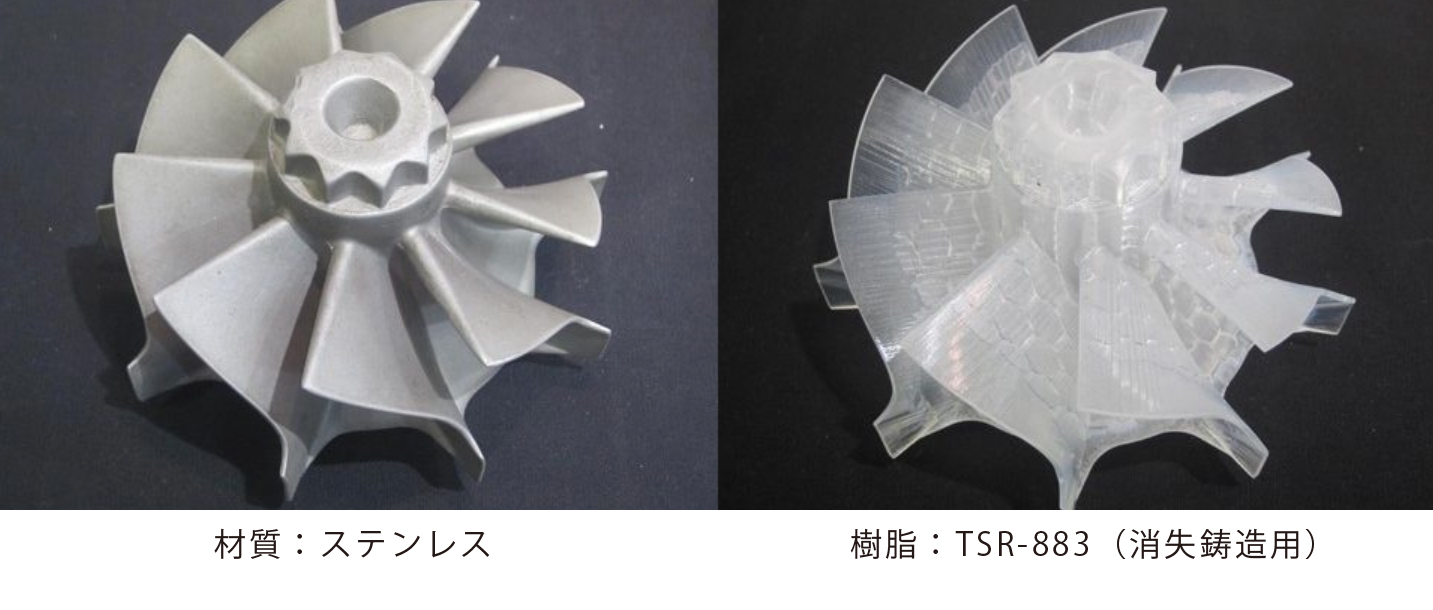

In conventional lost wax precision casting, a mold is manufactured at the first step to create a vanishing model (wax pattern) and then cast, but in the stereolithography precision casting method, the vanishing model is manufactured by stereolithography without using a mold.

[Several castings can be manufactured without the molds]

In conventional lost wax precision casting, a mold is manufactured at the first step to create a vanishing model (wax pattern) and then move to the casting process.

In the conventional method, since the mold is used, there are problems that the mold manufacturing cost cannot be recovered unless the quantity is a certain amount, and the mold manufacturing period tend to be longer, accordingly the delivery time cannot be shortened.

The stereolithography precision casting method can solve these problems because this vanishing model is manufactured by stereolithography instead of mold. Especially in situations where extremely small quantities of precision castings are required, such as prototypes in the early stages of development and small lot production, if the needs meet this method, both lead time and cost can be reduced.

Resin improvement significantly reduces “residue”, the combustion speed is improved, and the ease of casting is improved. Wax melts at high temperatures, but stereolithography is not melted but gasified and disappears. With conventional resins, a large amount of ash remains in the mold at that time, which often adversely affects the casting surface of the cast product. However, our antimony-free resin (TSR-883) was able to significantly reduce the residual amount of this ash.

As a result, the quality of the casting has also improved significantly.

In the stereolithography precision casting method, the ability of the most accurate and beautiful stereolithography among many additive manufacturing methods can be faithfully reflected in the casting. With a rough model such as powder molding(SLS), the casting surface of the cast product is also rough and post-processing is difficult, but such dissatisfaction can be resolved, and casting products that require accuracy that is difficult to adapt with a 3D printer. In particular, the turbo impeller and inverter case introduced in the photo are typical examples, and we have confirmed that problems will occur in all of 3D printers, powder molding and cutting, and we have confirmed that stereolithography precision casting I think this is a very good example for you to understand the merits of.

TSR-884 achieves high transparency visualization while maintaining heat resistance of over 100 ℃.There have been stereolithography resins that have better heat resistance than before, but there were only brown and colored ones, and no transparent either.

TSR-884 achieves high transparency visualization while maintaining heat resistance of over 100 ℃.There have been stereolithography resins that have better heat resistance than before, but there were only brown and colored ones, and no transparent either.

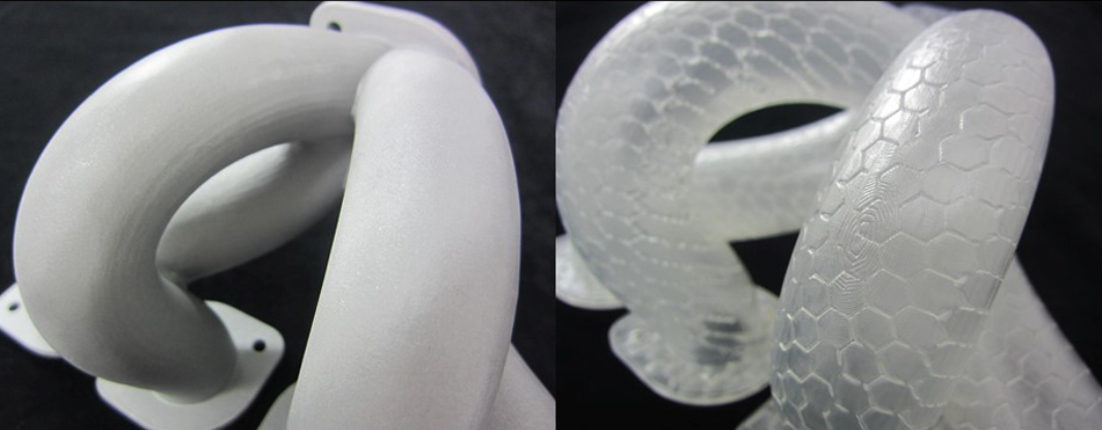

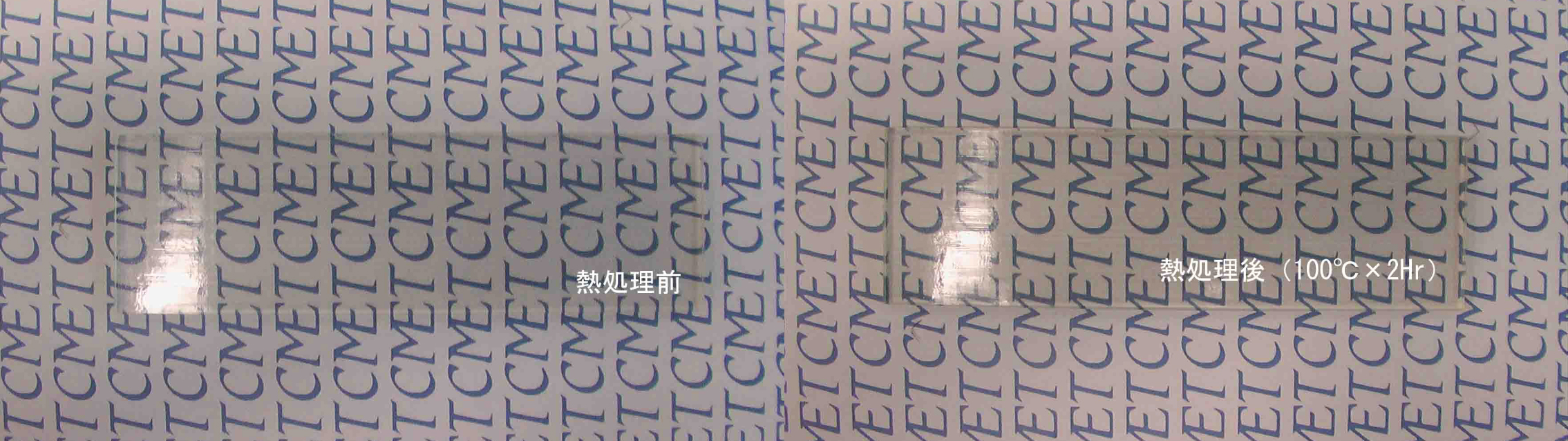

“TSR-884B” has heat resistance of over 100 ℃ by heat treatment, furthermore, extremely high transparency. If you compare the same shapes below, you can feel the high transparency of TSR884. This makes it easy to visualize without having to carefully polish the model.

The problem with conventional stereolithography resins is that when heat treatment is applied to improve heat resistance, the color of the model changes to brown, and visibility is impaired.

The transparent heat-resistant resin “TSR-884B” does not lose its transparency even if it is heat-treated, so its visibility is not impaired.

As you can see in the photograph, the yellow index and total light transmittance hardly change even after heat treatment.

This also means that visibility during heat resistance tests is unlikely decline.

The motivation for the development of the transparent heat-resistant resin “TSR-884B” is the need to evaluate the flow of liquid inside the engine.

Therefore, we dipped the sample flat plate in the engine oil and evaluated the color change and resistance.

Test method: Immerse the TSR-884B model in oil at 80 ℃ for 2 hours, 4 hours, and 6 hours.

Sample: 45 x 25 x 5 mm flat plate

Result: There is no significant change in hardness, yellowing, and transmittance.

“Deformation, dimensional change”, which was a typical example of the bad image of stereolithography resin, has also been greatly improved.

Moisture resistance. The value is less than half that of conventional resins.

This is an absolutely necessary performance, assuming that stereolithography products are used directly for evaluation tests that take several weeks, rather than simple shape confirmation as well as casting masters that may be used in a few days.

When removing the support, we use an art knife with a thick blade of 1 mm that does not bend or rattle while working on thin-walled, fine-shaped models.

When removing the support, we use an art knife with a thick blade of 1 mm that does not bend or rattle while working on thin-walled, fine-shaped models.

It may be easier to find a place to buy from a store that sells art tools and plastic models, or online, rather than D.I.Y. store.

Since the cutting edge has a double-edged finish, it can be used as a scraper.

Even more recommended the one with a brush on the other side.

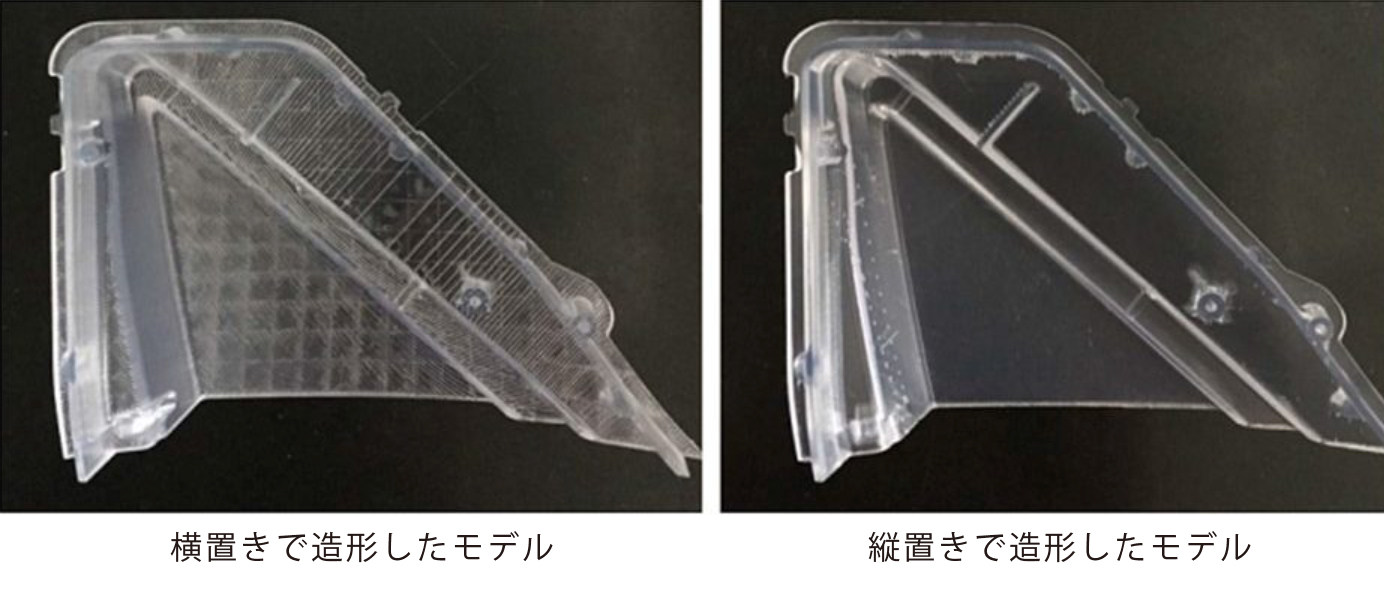

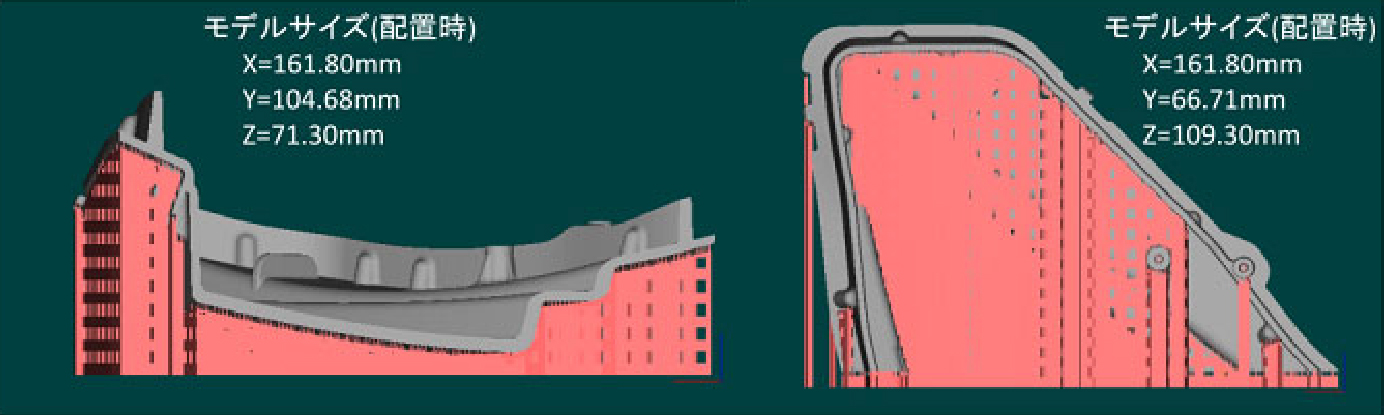

When modeling a model, the impression of the completed model changes depending on whether it is modeled horizontally or vertically.

When modeling a model, the impression of the completed model changes depending on whether it is modeled horizontally or vertically.

If the model is characterized by a gentle curved surface, the laminated steps on the gentle slope will be noticeable if it is placed horizontally.

On the other hand, the vertical model is beautifully completed.

The difference in the placement height of the model due to the difference in the modeling direction is 39 mm, but the modeling time of the horizontal lens and the modeling time of the vertical lens are about 1.5 times different. Even if the model has the same shape, it will take longer to model. This is because the height of the modeled object is the main factor that determines the modeling time.

The difference in the placement height of the model due to the difference in the modeling direction is 39 mm, but the modeling time of the horizontal lens and the modeling time of the vertical lens are about 1.5 times different. Even if the model has the same shape, it will take longer to model. This is because the height of the modeled object is the main factor that determines the modeling time.

We provide advice for users on the shape and modeling direction of the model, such as whether you want to shorten the modeling time, complete the model beautifully, or how to attach support so forth.

A sponge abrasive is a paper file with a sponge attached to the back, but it is a product that has both polishing power and flexibility, and it is recommended for easy to polish because it fits easily on curved surfaces due to the cushioning effect such as fine parts and edges.

A sponge abrasive is a paper file with a sponge attached to the back, but it is a product that has both polishing power and flexibility, and it is recommended for easy to polish because it fits easily on curved surfaces due to the cushioning effect such as fine parts and edges.

We use sandpaper and sponge abrasives properly according to the application. As with sandpaper, you can purchase sponge abrasives at D.I.Y stores.

* Since it is a soft material, we recommend using scissors to cut it into a size that is easy to use.

Our Yokohama Resin Development Center supports customers in introducing 3D printers.

The showroom is available for tours and demonstrations by appointment.

Please make a reservation and come to the showroom.

■Telephone inquiries TEL: + 81-45-478-5561 (Sales Department)

■Inquiries from the web form: Please make a reservation from here